Forging Business

- TOP

- Our Business

- Forging Business

Business Introduction

Forging Department of SNT Group is producing forged parts

with excellent technology and quality assurance.

with excellent technology and quality assurance.

Since its foundation, we have expand our forging business to overseas by overcoming many difficulties. We aim to be a company that contributes to the local community that is trusted by customers by using new matufacturing method and developing new product of course, and also “3 ZERO (quality, delivery time, safety) activity”, exclude 3M (Muri, Muda, Mura in Japanese), ensure 3R (Reuse, Reduce and Recycle).

What is forging

Forging is a manufacturing method that changes shapes by applying strong force to metal such as iron and build a product with sturdy and strong characteristics. It is used for mass-produced parts that require strength and safety, such as automobile parts, bolts/nuts and gears.

4 Advantages of SNT Group’s Forging Business

Advantages 01One of the best Forging Equipment owned in Japan

SNT Group has 3 types of forging equipment (press, hammer, upsetter) and can manufacture various forging products. Multiple forging is possible by combining each forging process, and we are able to handle complex shapes and large products. In addition, the 10-ton air drop hammer and 9-inch upsetter are remarkable forging machines in Japan.

We undertake integrated production from die design to finished products.

Manufacturing Process

Die Design / Production

We will make an appropriate die by utilizing the know-how.

-

01

Procurement of steel materialsWe obtain traceable steel products from reliable suppliers.

Procurement of steel materialsWe obtain traceable steel products from reliable suppliers. -

02

CuttingCan be used with a variety of steel materials from small to large diameters.

CuttingCan be used with a variety of steel materials from small to large diameters. -

03

HeatingAbout 1,200 ℃ by atmospheric heat treatment or induction heating.

HeatingAbout 1,200 ℃ by atmospheric heat treatment or induction heating. -

04

Die Forgin / TrimmingBy appropriate forging machine

Die Forgin / TrimmingBy appropriate forging machine -

05

Heat TreatmentAdjust strength and machinability according to the purpose.

Heat TreatmentAdjust strength and machinability according to the purpose. -

06

In-process inspectionWe use a wide variety of inspection machines to inspect and test the quality required by our customers.

In-process inspectionWe use a wide variety of inspection machines to inspect and test the quality required by our customers. -

07

MachiningBy BTA(deep hole drrilling), lathe, and gear hobbing machines

MachiningBy BTA(deep hole drrilling), lathe, and gear hobbing machines -

08

Induction HardeningQuenching is performed only on the surface. Both wear resistance and toughness can be achieved.

Induction HardeningQuenching is performed only on the surface. Both wear resistance and toughness can be achieved. -

09

Final InspectionWide variety of inspection machines for pre-shipment inspection.

Final InspectionWide variety of inspection machines for pre-shipment inspection. -

10

Shipping

Shipping

We SNT have established an integrated production system that covers the entire process including steel procurement, cutting, forging, heat treatment, inspection, machining, induction hardeing and shipping. That system allows us to maintain a high and stable quality level by conducting strict quality checks in all processes and immediately sharing quality information between processes. We also design and manufacture our own dies, which are the core technology of die forging, and can manufacture appropriate dies at any time by incorporating our accumulated know-how and quality implovement.

Advantages 02SNT’s technological strength supported by continuous improvements at the production site

We are proud of our on-site implovements, which are supported by a variety of craftsmen. Due to the development of digital technology in recent years, the craftsmanship is not required as much as before in the field of manufacturing. However, at SNT, we aim to be craftsmen who can e improved in any situation and a set a value of “actual process,” “actual products,” and “facts” . As a group, we are repeating technical exchanges with the aim of sharing know-how, experience, and technology to enhance each other. No matter how difficult the problem may be, we aim to create products that will satisfy our customers with the saying “two heads are better than one.”

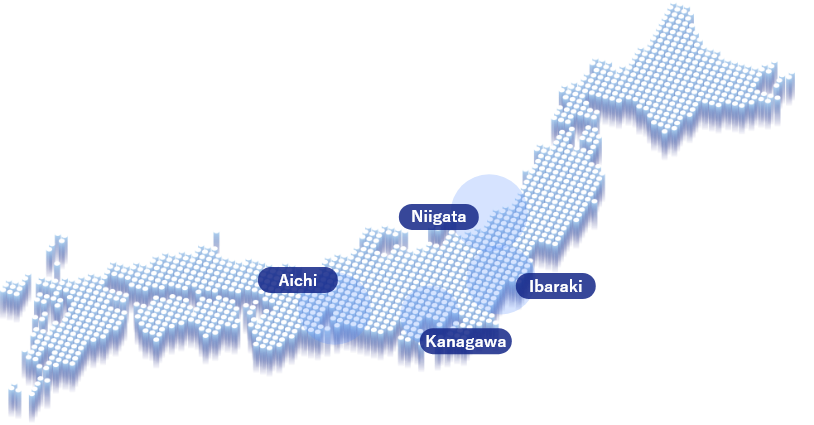

Advantages 03SNT Group Forging Factories

Our group’s forging plants are located in four locations in Japan and overseas, and we have earned the trust of our customers in terms of risk management and contingency plans for our suppliers.

Advantages 04Research and Development (R&D) Activities

By creating new value and contributing to society, we aim to achieve sustainable, medium- to long-term improvements in corporate value.

Take an action to new technology / automation

- Research on die surface treatment method (technology) using laser.

- Research on defect detection by image processing using AI.

- Automation of removing a flash after forging.

- Handling / inspection automation / labor saving