- TOP

- Our Business

- Forging Business

- Forging Products

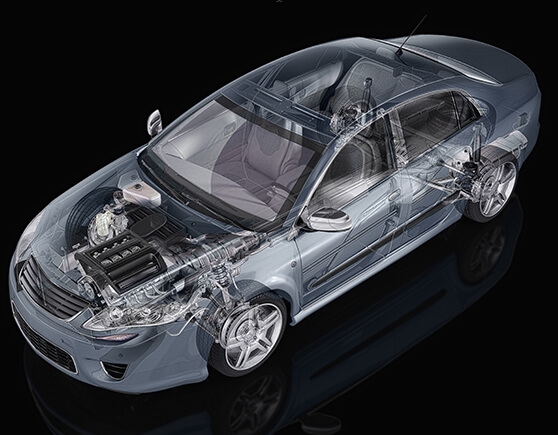

Trucks and Automobiles

At SNT, we forge a variety of parts that make up vehicles, such as steering parts, axles, and drive parts.

In particular, we have extensive experience in the production of important safety parts, which are components of the basic performance of vehicles.

Especially, forging knuckles are highly evaluated by our customers according to their complex shapes and spindles,

We are also capable of forging cylindrical parts, called hollow parts, with high yield using our original technology, and we provide parts of various sizes.

Product examples

-

Knuckle

Size: 490×260mm

Weight: Approx. 14kg

SNT’s original producting process enables us to forge products with complex shapes and long spindles that are highly difficult to forge.

-

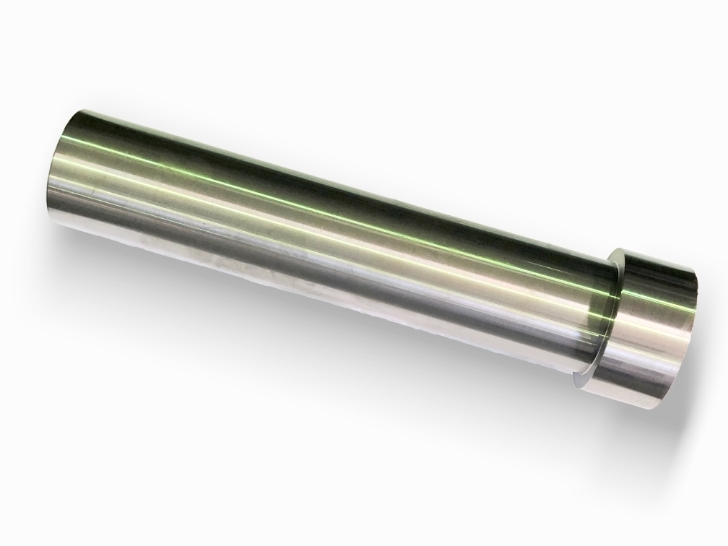

Tube

Size: φ150×315mm

Weight: Approx. 13.6kg

Hollow parts can be forged with high yield by forming the inner diameter hole deeply and penetrating it.

We have machining facility in Takahagi factory, which enables integrated production from forging material to finished products. -

Pinion

Size: φ130×260mm

Weight: Approx. 6.1kg

We can forge both short and long shaft parts. Forging rolls (pre-former equipment) can make them with high yield. (except for some long products)

Construction machinery and forklifts

We provide parts for a variety of construction machinery and special vehicles, including excavators, forklifts and wheel loaders.

In order to meet various needs of our customers, We have a lineup of forging equipments with industry-leading capabilities.

Taking advantage of the features of each forging equipment, we also offer composite forging by combining different forging machines (press + upsetter, upsetter + hammer, etc.).

Product examples

-

Sprocket (Hydraulic Excavator)

Size: Approx. φ660×70mm

Weight: Approx. 50kg

Large tooth-shaped parts that rotate crawlers of excavators are forged using one of Japan’s leading 10-ton air drop hammers.

-

Shaft (Forklift )

Size: φ190×670mm

Weight: Approx. 15.6kg

Available in various sizes (shaft diameter, length, outer diameter).

The spline part is forged by an unmanned robot.

We have a machining factory enables integrated production from forging to finished products. -

Large shafts (Special Construction Vehicles)

Size: φ370×790mm

Weight: Approx. 96.3kg

Combined forging process (upsetter and air drop hammer) is performed. The shaft part can be forged in a straight shape with no extra machining allowance due to the extraction angle.

Others

SNT provide a variety of large and small parts, mainly for engine parts (generators, etc.) and machinning tools.

In addition, we have identified the renewable energy field as a field in which it will focus its efforts in the future.

Examples

-

Camshafts

Size: Approx. φ90×1670mm

Weight: Approx. 50kg

Camshafts in a variety of sizes, both large and small. We produce high-precision forged products with minimal bending.

-

Connecting Rods

Size: Approx. 350 x 900mm

Weight: Approx. 90kg

We can provide a variety of sizes. Rough forming with forging rolls and free hammers can be used to forge with high yield. (mainly for engine generators and ships)

-

Spindles

Size: Approx. φ175×500mm

Weight: Approx. 47kg

Spindle parts for machine tools are forged in our factory. Compared to rotary machining from thick round material, cost can be significantly reduced. Rough turning and through hole drilling (BTA) are also available.