Manufacturer of forged products, scaffolding parts, logistics equipment,

listed on the 1st section of the Tokyo Stock Exchange.

We utilize high-speed carving machines to shorten fabrication time and reduce manual finishing. We aim at improving productivity while manufacturing 100% in-house.

In-house facilities:

- 3 NC turning machines

- 1 large multi-purpose turning machine

- 7 machining centers (2: high-speed carving machines)

- 1 ion-nitriding machine

- 3 NC turning machines

- 1 large multi-purpose turning machine

- 7 machining centers (2: high-speed carving machines)

- 1 ion-nitriding machine

We are capable of hardening, tempering (both water tempering and oil tempering), normalizing, and annealing. We aim at maintaining and improving heat treatment quality.

In-house facilities:

- 1 continuous furnace (For hardening and tempering. Processing capacity: 1.5 t/h)

- 2 hardening batch furnaces (Processing capacity: 1 t/batch)

- 4 tempering batch furnaces (Processing capacity: 1 t/batch)

- 1 continuous furnace (For hardening and tempering. Processing capacity: 1.5 t/h)

- 2 hardening batch furnaces (Processing capacity: 1 t/batch)

- 4 tempering batch furnaces (Processing capacity: 1 t/batch)

About 30% of the products we supply are machined products. Machining enables overlap widening and deburring labor to be reduced. We aim reducing the total cost of parts.

In-house facilities:

- 8 special-purpose processing lines (Tsukuba Koki)

- 8 special-purpose processing lines (Tsukuba Koki)

We utilize 3-dimensional measuring instruments and contracers to inspect the parts we machine.

We also own a material test suite including tensile testers, impact testers, and metallographic microscopes.

We aim at zero defects from our in-house manufacturing processes to the delivery process.

In-house facilities:

- 1 3-dimensional measuring instrument

- 1 contracer

- 1 material tester

- 1 3-dimensional measuring instrument

- 1 contracer

- 1 material tester

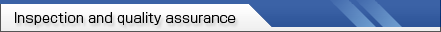

- Forging roller

When material is charged, a photosensor detects it and the machine starts rolling immediately at a rate of 1 cycle (4 passes) per 9 seconds at maximum. Its traverse feeding precision is within +-1 mm. The roll drive gear has large additional modifications, so with a high gear side and bending strength there are almost no problems such as tooth damage caused by rolling operation impacts.

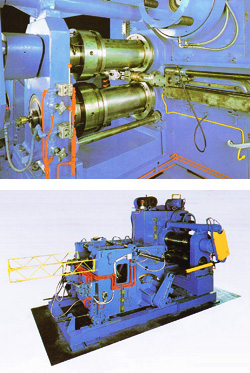

- Manipulator

The lightweight traverse frame can follow the roll rotation speed smoothly. Traverse feeding is controlled by hydraulic servos, so the traverse feeding pitch can be adjusted arbitrarily. The traverse feeding control equipment consists of our original servo controller, hydraulic cylinder, hydraulic servo valve, etc., and provides a simple yet robust solution at a reasonable cost.

This product is manufactured by Tsukuba Koki. We can offer various optional services including the modification of third-party products. Please contact our Forging Business division for further information.